Custom Jewelry

Custom Design Creation

Claudia’s Jewelry Inc. Specializes in Custom Jewelry designing, any idea the customer has for a special made piece we can turn it into reality. Whether the customer has a design already or would like to modify their own design we will gladly help. We can also help the customer create their own custom design, we will suggest the best method based on their specifications.

Whichever path we take to create your unique custom design, the customer can be assured that the highest level of detail and attention will be given to each piece that we create at Claudia’s Jewelry Inc and guarantee total satisfaction, once the final touch is given to the piece that was made.

Customers can come in and set an appointment with our specialized jewelry designer to start a special made design. He will gladly assist you in whether you are looking to make an unusual piece of jewelry, or have an idea for something different. Our designer will listen to what you are interested in having made.

Step-by-Step On How We Make Our Custom Jewelry Designs

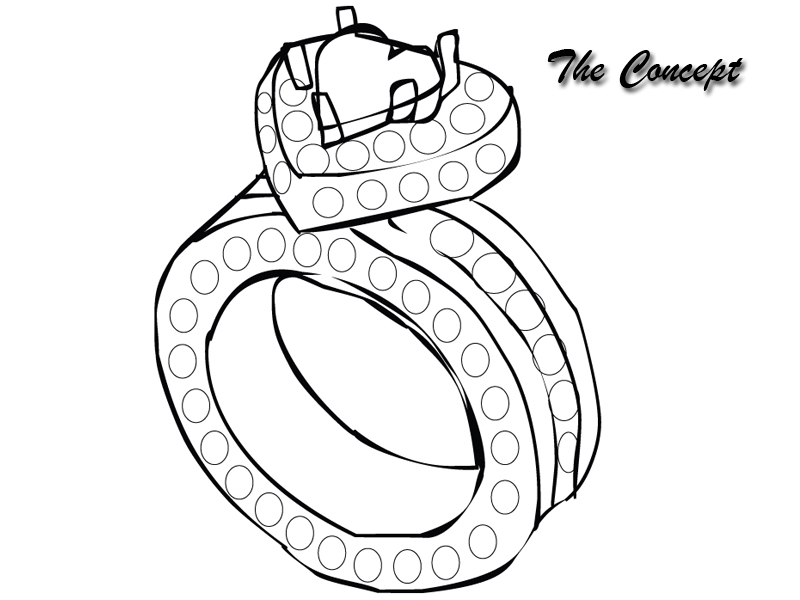

STEP#1 Sketching Idea

The first step to start a custom design is sketching out any idea of the desired jewelry piece to be made. We put down the design on paper as a simple sketch with dimensions and specifications. For example ring size 7, center stone, metal type etc.

This allows the designer to have a better concept of what exactly is going to be worked on. A sketch features only enough detail to guide the designer through the project.

Sometimes drawing or sketching serve for two purposes: one to help the customer visualize how the product will look , and second to guide the designer craft the piece. Also from drawing the customer & designer can discuss any feasibility and style. At this stage the design can be easily modified to accommodate any dislikes.

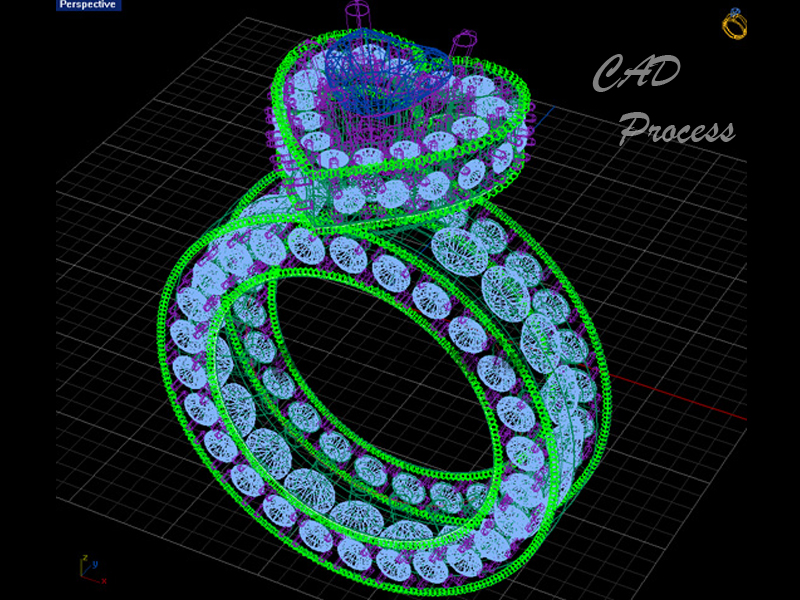

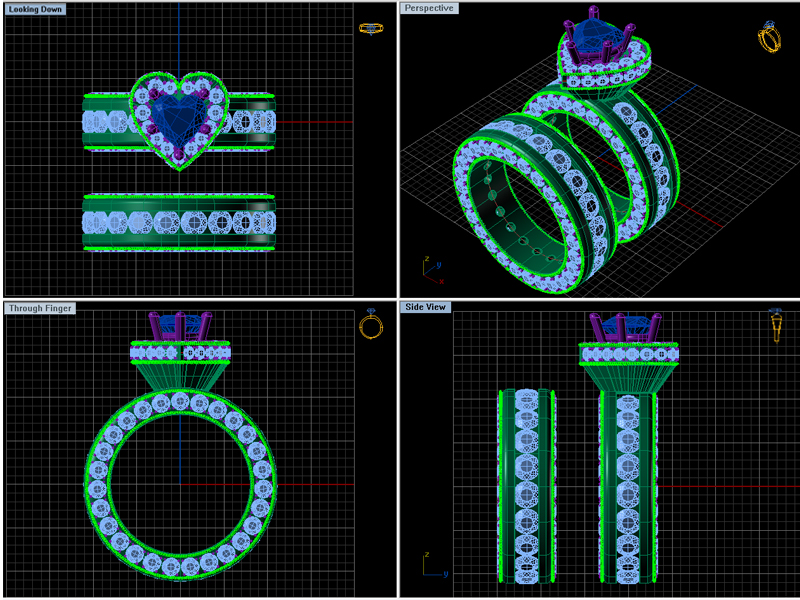

STEP#2 CAD Process

We transfer the idea to the CAD program , CAD means Computer Aided Design. CAD-CAM is a tool used by the designer to obtain the details and precision in designs that were impossible to do before. This program is used to establish exact measurements of the piece being made.

The CAD program will do the drawing design according to the specifications and preferences provided. Through computer aided design, the designer can apply stones to a setting, or anywhere the piece will require and allow the customer to have a better review of how the piece will look before it’s actually made.At this point the customer still has a chance of making any changes to any dislikes on the piece being made.

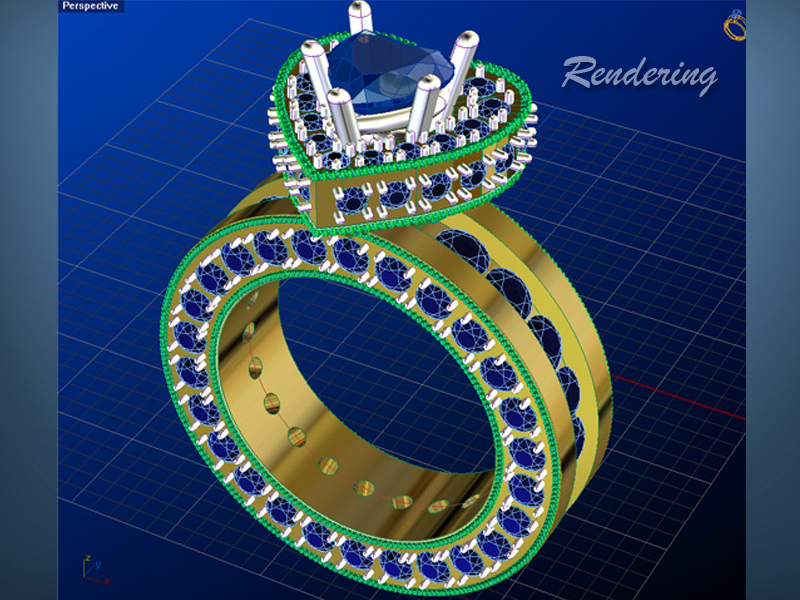

STEP#3 Jewelry Rendering

(Computer Aided Design) Allows the customer to see the piece before it exists, Rendering is the process of generating an image from a model.

After the finished CAD model is made then designer can render a photo –like image to simulate the appearance of how the piece would finally look.This rendering projection will enable the designer and customer to visualize the final project.

The designer will take time and go over every aspect of the design with the customer, he will do as much revision required to achieve the look that is desired.Once it is approved it goes to the final step.

STEP#4 Wax (Milling) Procedure

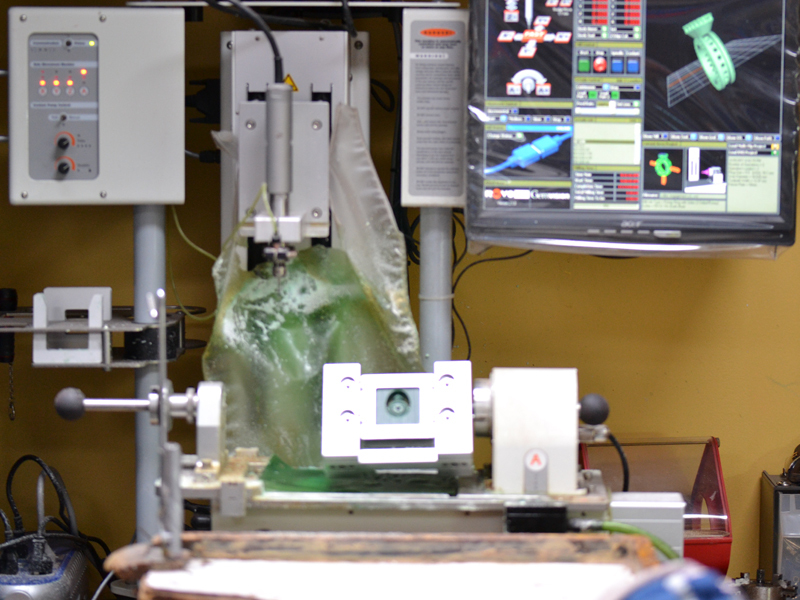

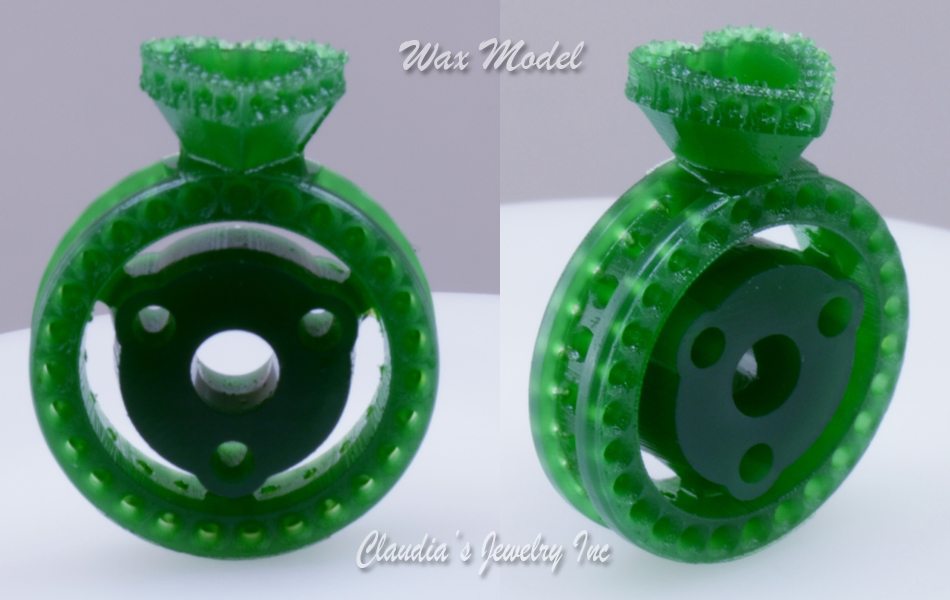

Upon final approval the designer will produce a wax model using the Revo 540 Multiple Axis Milling System this machine is specifically designed as a companion For the Gemvision Matrix Software.

The wax model is produced and made by the Revo 540 at our location. The use of this machine is a great idea to cut & mill fast and precise, and leave the wax ready for the following step.

On-Site Custom Made Jewelry Design

Master jeweler on duty 6 days a Week with over 25 years experience. Same day repair or while you shop! We Repair what others can’t

We Appreciate your Business

We know that keeping our customers satisfied is what keeps them coming back. We will go the extra mile to meet the needs of our clients.

No repair job is too small or too big for us

Our master jeweler have encountered nearly every jewelry repair scenario imaginable. We are happy to take on any repair challenge.

high-quality service Since 1997

We only use the best quality meterials, Integrity and Reliability has Earned Us a Reputation that is Unsurpassed.

STEP#5 Wax Investment

Once the wax model is milled we take the approved wax and attach (sprews) it to a tree using a hot wax pen. The wax tree is then covered with a flask and filled with investment. We use the highest quality investment with proven burnout cycles to yield excellent casting results. The investment dries and the flask is inserted into an oven to burn out the wax, which is also called lost wax casting.

After the investment is poured into the flasks, it is placed in a vacuum chamber to remove any trapped air before it is allowed to cure.

STEP#6 Wax Burn Out

Once the investment has hardened, the rubber sprue base is removed and the mold is ready for the wax removal process, then the flask is placed into an oven to be incinerated.

The flask is placed in a special oven where the wax will be incinerated at high temperatures of 1550 F for approximately 12 to 16 hours.

When the flask is burned out it has no remaining residue of wax. What remains is a hollow impression of the tree, and the design that was placed inside and burned from it.

The empty cavity of the flask that was burned out, will be filled with gold and the result is the piece being made but now finished in either yellow gold, white gold, platinum, or silver.

STEP#7 Melting & Casting Procedure

Casting is the process where liquid metal is forced into a mold and cools into a particular shape. Jewelry casting is often accomplished with lost wax casting.

The opening in the flask where the wax was burned from is lined up with a spout on a crucible. Once the metal is at a right temperature the centifruge being used will be released and the gold will freely flow through the spout into the empty cavity in the flask.

Once the flask and the metal that was used to make the piece of jewelry is cooled.The piece is then broken out of the investment, and clipped from the tree. Finally the piece comes out already made in the metal type that was chosen.

STEP#8 Final Process

The custom design is now completed it is sent to our bench jewelers for inspection and fix any imperfections it may have.

Our trained jewelers work with the best equipment to give the customer’s piece an outstanding look, and for necessary stone or diamond setting.

And any final touch ups followed by polishing. By now the piece should be finished and completed by now to give to the customer

Final Piece